IMT LASER PIGTAILS

ADVANTAGES:

- Hermetic seal without metallization and soldering

- Heat dissipation in fiber through metal ferrule

- Maintains ferrule concentricity for fast alignment

- Front and/or rear mechanical mount for environmental performance

Hermetically sealing optical fiber to the package wall of a photonics device has been a limiting process, both in terms of cost and ability to

automate production. Metallization of glass fiber that has been stripped of its protective polymer buffer coating is necessary in order to provide

a hermetic seal to the fiber by solder attachment. Metallization of the fiber requires batch processing of fiber pigtails by either thin film metal

deposition or by electroless plating. These processes are costly, have limited throughput, and are often subject to processing yield loss.

The need to metallize optical fiber is eliminated by Impact Mount™ Technology (IMT). Attachment of metal ferrules to the fiber is performed in one

quick mechanical action, that is naturally compatible with machine process automation.

The metal ferrule accomplishes two things:

The metal ferrule accomplishes two things:(1) Hermetic seal of the fiber feed-through to the package wall;

(2) Optical coupling attachment of the fiber to optical benches within the package.

Attachment of the ferrule may be by laser weld or solder processing. Fiber pigtail configurations supplied for photonic devices using IMT are shown in Figure 2 below.

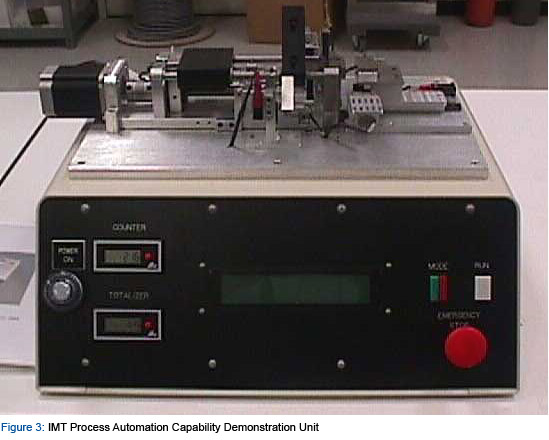

The IMT process is one quick efficient mechanical step that is well suited for machine automation. Figure 3 below shows a technology demonstration unit for IMT process automation. This type of IMT automation island can be installed within industry standard "pick'n'place" automated equipment to realize low cost, high volume production of fiber pigtails. The fiber pigtail preparation may also be readily integrated with automated alignment and attachment stations when using IMT to attach ferrules onto fiber pigtails.